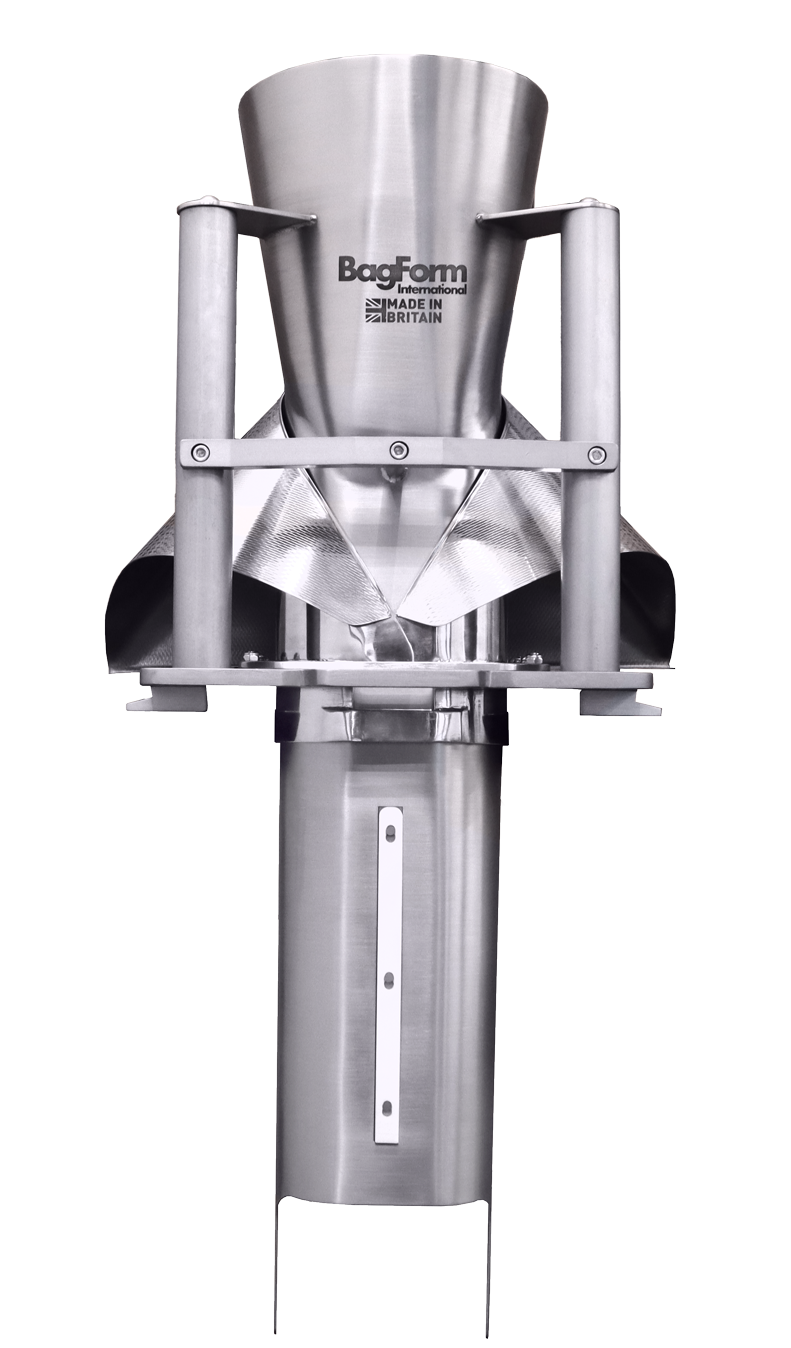

A wide range of options are available for our bag formers and bag forming sets, allowing you to create the right bag former for your business.

From sound-deadening coatings and insulation tubing to lightweight and high product flow applications, we can create the right bag former for you.

Our bag formers are able to run a wide variety of films, saving you time and money.

A large range of options are available to suit your business needs and we also produce a range of bag formers suitable for multi-packing.

Our bag-forming sets can run with all types of VFFS machines, including leading brands such as Sandiacre, Ishida and Ilapak.

Ceramic coatings seal the micropores on metalwork and provides extra protection for your bag former.

Teflon coatings for your forming sets allow for easier cleaning, reduce blockages and increase product output.

Our noise reduction coatings dampen the noise of products being processed. Enabling a safer working and packing environment.

Our dual chrome coatings provide extra resistance to wear and tear, making your bag forming sets last longer.

Our Insulation Tubing option is perfect for packing temperature sensitive products such as frozen foods. The tubing helps maintain the ideal product temperature during the packing process.

Our bag formers and bag forming sets can be made lightweight through our weight reduction process. This process ensures the formers are easy to remove whilst retaining their strength and durability.

Our high flow option improves the product flow capabilities of your bag formers.

Allowing for more product to pass through and increasing your production turnaround time.

Introducing our patent pending VFFS back sealing solution.

This innovative approach provides manufacturers with a consistent back seal whilst maintaining high production output speeds.

Additionally, it removes the need for a velcro seal strip and reduces the risk of foreign body contaminants.

Ady Dewar, Operations Manager for BagForm International, said, “We are incredibly excited to launch this patent-pending innovation to the VFFS industry. This showcases our commitment to providing our customers with innovative VFFS solutions.“

We’re excited to launch our VFFS Forming Set Lifter, designed to make handling and installing forming sets safer, easier, and more efficient than ever!

Whether you’re dealing with frequent changeovers or heavy-duty forming sets, our lifter ensures a seamless, secure process every time.

BagForm offers a comprehensive range of tube closers and strippers, expertly refurbished or manufactured to OEM specifications for optimal performance.

Designed for precision and durability, our solutions ensure secure bag sealing and efficient stripping, minimising waste and downtime. Whether you need a cost-effective refurbishment or a new custom-manufactured component, BagForm delivers reliable solutions tailored to your VFFS machine requirements.

Our refurbishment service provides a cost-effective solution to get your forming sets back on the production line and reduce downtime.

We offer a fast turnaround time and can come to you with our mobile refurbishment solution.

Collection & Delivery services available

Copyright BagForm 2024

BagForm International is a trading name of Alway Loughborough Ltd

Built by Vandal Marketing